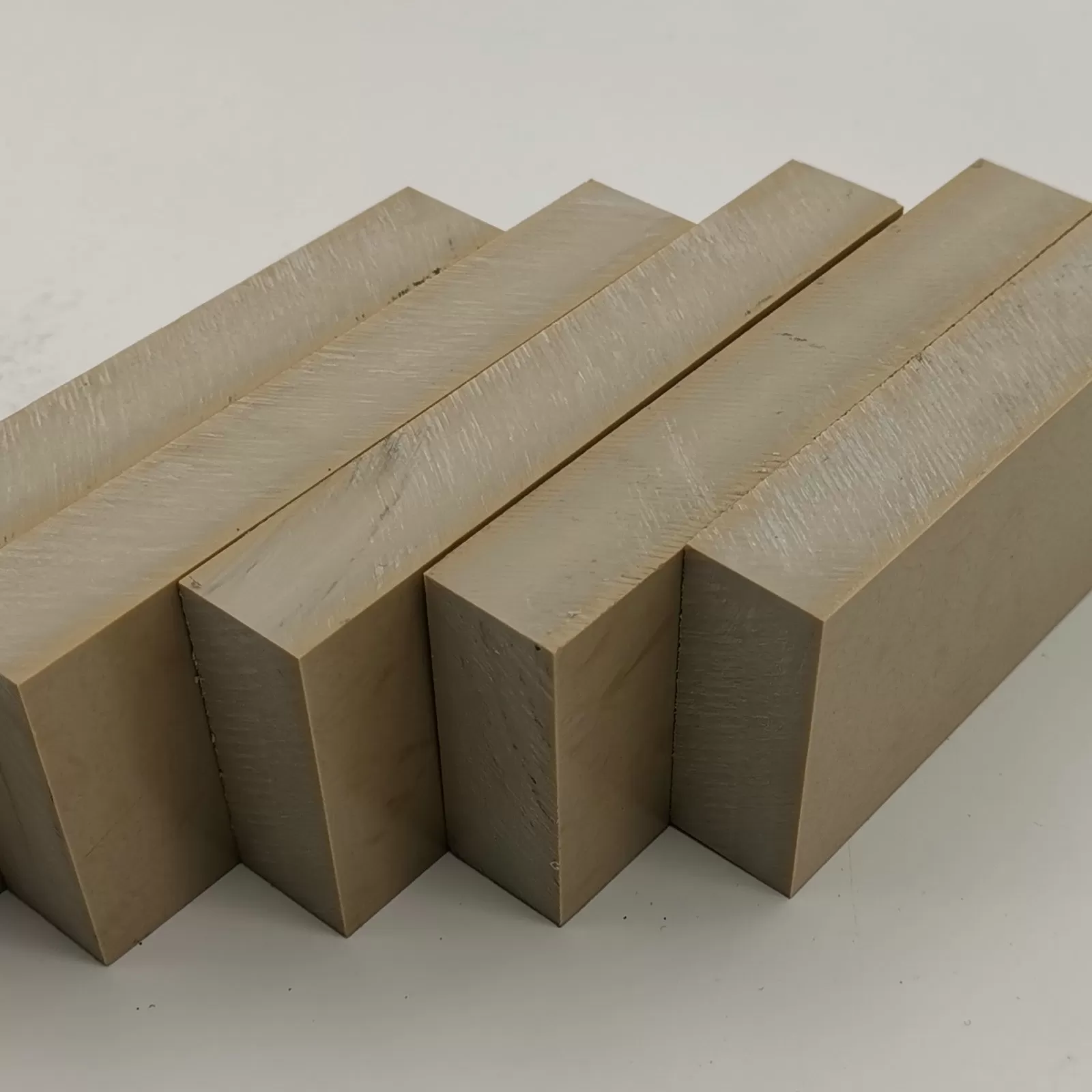

Precision PEEK Cutting

Our precision PEEK cutting services provide custom-sized and shaped materials for machining applications. We utilize advanced techniques like laser cutting and CNC machining, ensuring accurate cuts and minimal material waste. Our expertise covers a range of PEEK materials, including glass-filled and carbon-filled variants.

_______________________________________________________________________________________________________________________________________________________________________

Introduction to Precision PEEK Cutting

Precision PEEK cutting is a specialized process that requires careful attention to detail due to the material's unique properties. PEEK is a high-performance thermoplastic known for its excellent mechanical strength, chemical resistance, and thermal stability, making it ideal for critical applications in aerospace, automotive, medical, and industrial sectors.

PEEK Mechanical Properties

PEEK materials exhibit outstanding mechanical properties, including high tensile strength, stiffness, and resistance to fatigue. These properties make PEEK a preferred choice for precision parts that require durability and reliability under extreme conditions.

Cutting Techniques for PEEK

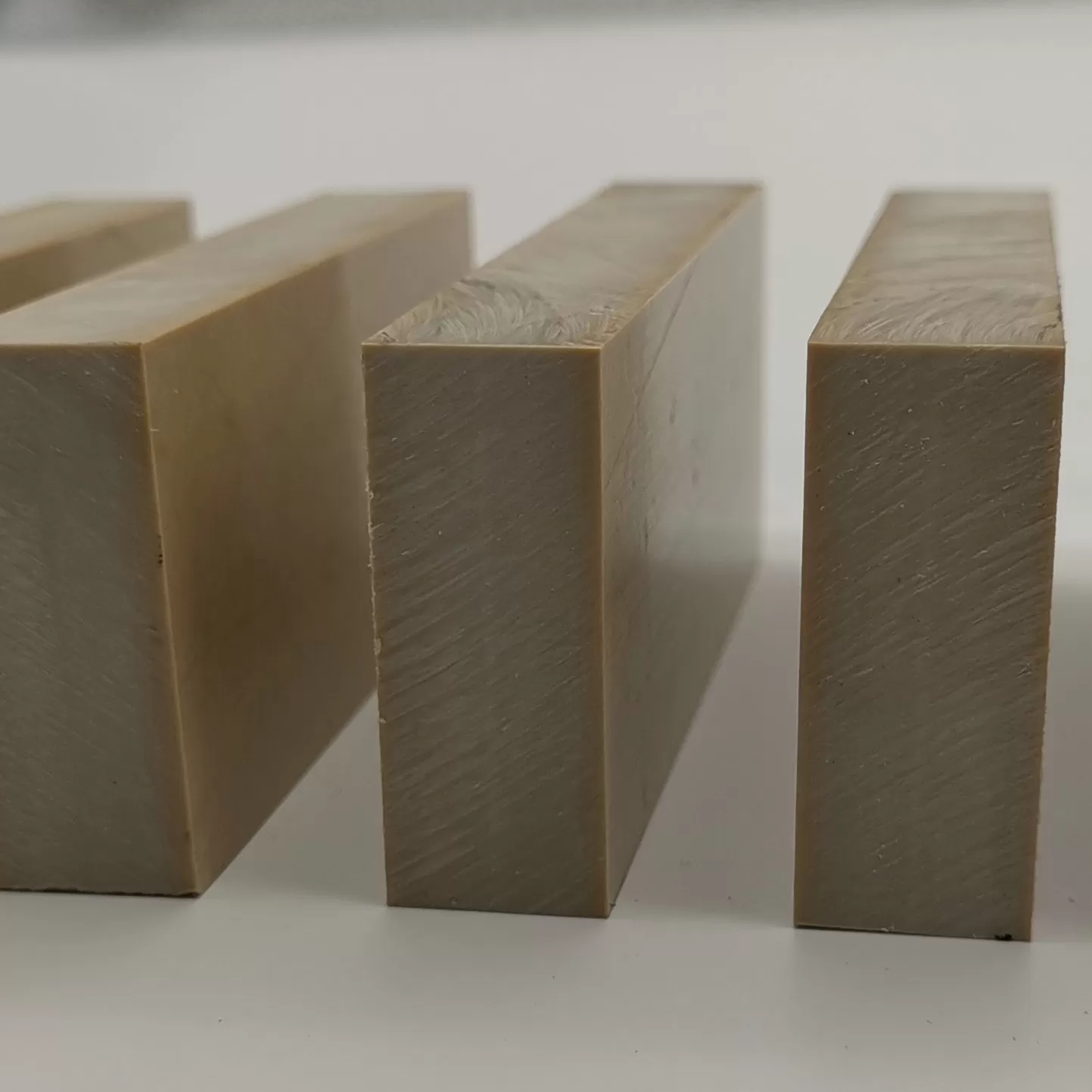

Laser Cutting PEEK: We utilize advanced laser technology to cut PEEK materials with precision. Laser cutting offers clean edges, minimal darkening, and the ability to create complex profiles, making it ideal for applications requiring tight tolerances.

CNC Machining: Our CNC machining services ensure high accuracy and repeatability, crucial for intricate components. We use specialized cutting tools such as silicon carbide and diamond tools to minimize errors and enhance cutting efficiency.

Cutting Speed and Tools: The cutting speed for PEEK typically ranges from 500 to 800 m/min, depending on the tool type and material thickness. We select cutting tools based on the specific PEEK variant and application requirements to optimize results.

How to Cut PEEK

Cutting PEEK requires careful consideration of tool selection, cutting speed, and material preparation. Preheating the material can improve cutting efficiency, especially for carbon-filled variants. Our experienced technicians ensure that each cut is executed with precision, minimizing material waste and maintaining the integrity of the PEEK material.

_______________________________________________________________________________________________________________________________________________________________________

Cutting PEEK Materials

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. Improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.